glow in the dark epoxy resin harga jb weld steel reinforced jdiction uv laticrete

Glow in the Dark Epoxy Resin, Harga JB Weld, Steel Reinforced, and UV Laticrete: An In - Depth ExplorationGlow in the dark Epoxy Resins, Harga JB Welds, Steel Reinforced and UV Laticretes: An In-Depth Exploration

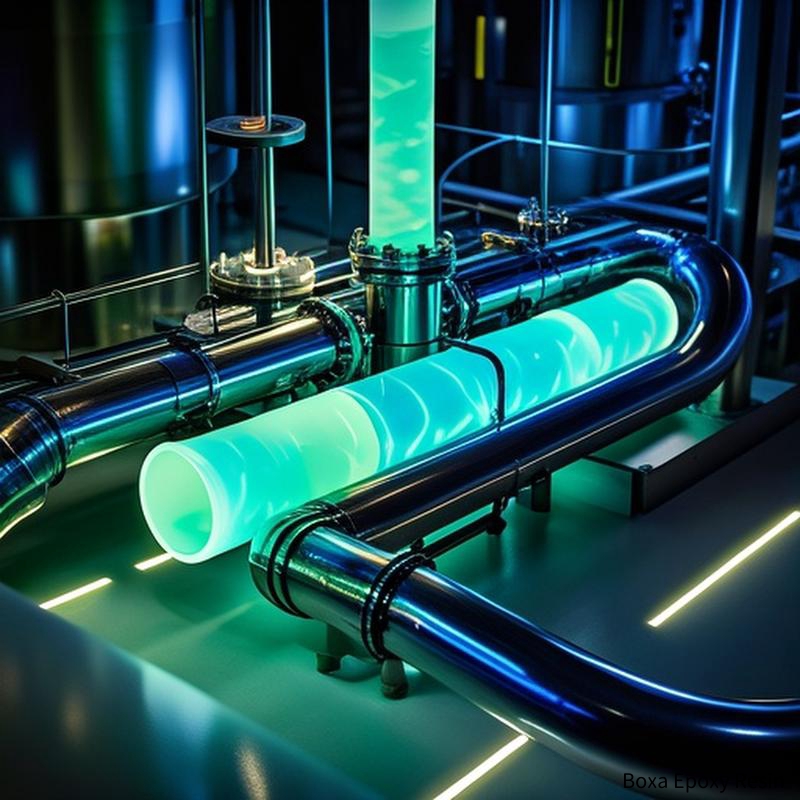

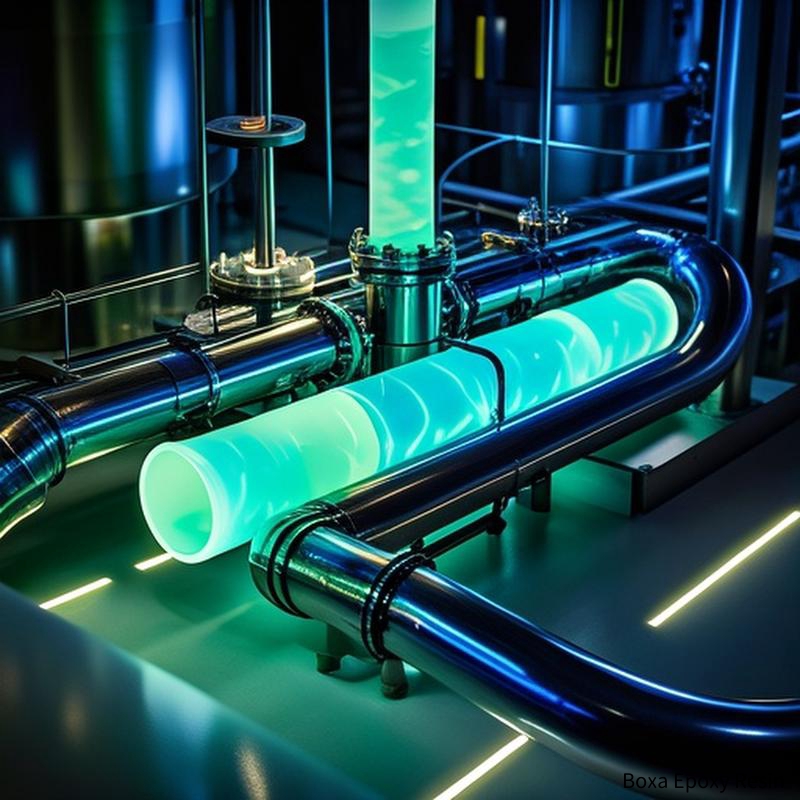

Glow in the dark epoxy resin has emerged as a fascinating material in the world of DIY projects, art, and even some industrial applications.Glow in dark epoxy resin is a fascinating material that has been used in DIY projects, arts, and even industrial applications. This unique resin contains phosphorescent pigments that absorb light during the day or when exposed to artificial light sources and then emit a soft, glowing light in the dark.This unique resin contains pigments that absorb daylight or artificial light and emit a soft glowing light at night. The applications of glow in the dark epoxy resin are vast.Glow in the dark epoxy resin has a wide range of applications. In interior design, it can be used to create eye - catching floors, countertops, or even decorative wall panels.It can be used in interior design to create eye-catching floors, countertops or decorative wall panels. Artists often utilize it to add an otherworldly touch to their sculptures or paintings, making their works stand out in the dark.Artists use it to give their paintings or sculptures an otherworldly feel, allowing them to stand out at night.

When considering the use of epoxy resin, price is an important factor.Price is a major factor to consider when considering the use and application of epoxy resin. "Harga" is the Malay word for price, and understanding the cost of glow in the dark epoxy resin is crucial.Understanding the price of glow-in-the dark epoxy resin, or "Harga", is important. The price can vary depending on several elements.The price can be affected by several factors. The quality of the resin itself, the concentration of the glow - in - the - dark pigments, and the brand all play a role.The brand, the quality of the resin, and the concentration of glow-in-the-dark pigments all play a part. High - quality resins with a high pigment load will generally command a higher price.High-quality resins with high pigment loads will command a higher cost. Additionally, the quantity purchased can also affect the per - unit cost.Quantity can also influence the cost per unit. Larger volumes often come with a more favorable price per liter or gallon.The price per liter and gallon is often more affordable for larger volumes.

JB Weld is a well - known brand that offers a range of repair and bonding products.JB Weld offers a wide range of repair and adhesive products. Their steel - reinforced formulations are particularly popular.The steel-reinforced formulations of JB Weld are especially popular. The steel - reinforced JB Weld is designed to provide a strong, durable bond, especially when dealing with metal surfaces.Steel-reinforced JB Weld provides a strong and durable bond, particularly when working with metal surfaces. It contains steel particles that enhance the strength of the bond, making it suitable for heavy - duty applications.It contains steel particles which increase the bond strength, making it ideal for heavy-duty applications. For example, in automotive repair, it can be used to fix cracked engine blocks or exhaust systems.In automotive repair, for example, it can be applied to fix cracked exhaust systems or engine blocks. In industrial settings, it can be used to repair machinery parts that are under significant stress.In industrial settings it can be used to repair machinery that is under stress. The "harga" of JB Weld steel - reinforced products also depends on factors like the size of the container and the specific formulation.The price of JB Weld's steel-reinforced products is also affected by factors such as the size of the container or the formulation. Larger tubes or containers of this high - performance adhesive will typically cost more, but they can be more cost - effective for larger projects.The cost of larger tubes or containers will be higher, but can be more cost-effective for large projects.

UV laticrete is another interesting product in the construction and finishing materials market.UV laticrete is a product that is interesting in the construction materials and finishing materials market. Laticrete is a brand that is known for its high - quality tile and stone installation products.Laticrete is known for its high-quality tile and stone installation materials. UV - cured laticrete products are designed to be cured or hardened when exposed to ultraviolet light.UV-cured Laticrete products are designed for curing or hardening when exposed to ultraviolet radiation. This offers several advantages.This has several advantages. The curing process is much faster compared to traditional drying methods, which can save time on construction sites.The curing process can be much faster than traditional drying methods. This can save time at construction sites. It also provides a more consistent and durable finish.It also produces a more durable and consistent finish. In applications such as installing countertops or tiling floors, UV laticrete can ensure a strong bond between the tiles and the substrate.UV laticrete is ideal for applications such as installing counters or tiling flooring. It can ensure a strong connection between the tiles and substrate. The use of UV - curing technology also reduces the risk of issues like shrinkage or uneven drying that can occur with other adhesives.UV-curing technology reduces the possibility of shrinkage and uneven drying, which can occur when using other adhesives.

When we combine these elements - glow in the dark epoxy resin, steel - reinforced JB Weld, and UV laticrete - we can envision some truly innovative projects.We can imagine some truly innovative projects when we combine these three elements - steel-reinforced JB Weld and UV laticrete. For instance, in a large - scale industrial art installation, glow in the dark epoxy resin could be used to create a base layer on a metal structure that has been pre - repaired or reinforced with JB Weld steel - reinforced adhesive.In a large-scale industrial art installation, for example, glow in dark epoxy resin can be used as a base coat on a metal structure which has been pre-repaired or reinforced with JB weld steel-reinforced adhesive. Then, UV laticrete could be used to attach decorative tiles or stones to the surface, adding another layer of texture and design.Then, using UV laticrete, decorative tiles or stones could be attached to the surface to add another layer of texture. The result would be a unique, illuminated structure that not only looks great during the day but also comes alive in the dark.The result would be an illuminated structure with a unique look that is not only beautiful during the day, but also vibrant at night.

In conclusion, glow in the dark epoxy resin, JB Weld steel - reinforced products, and UV laticrete each offer unique features and benefits.Conclusion: Each of the products mentioned above, JB Weld Steel-Reinforced Products, UV Laticrete, and glow in dark

epoxy resin have unique features and advantages. Whether you are a DIY enthusiast, an artist, or a professional in the construction or manufacturing industry, understanding these materials, their applications, and their prices (harga) can open up new possibilities for your projects.Understanding these materials, their uses, and their price (harga), can help you create new possibilities, whether you are a DIY enthusiast or a professional working in the construction industry or manufacturing. By carefully considering how to combine these materials, one can create products and structures that are both functional and aesthetically appealing, meeting the demands of various industries and creative endeavors.By carefully combining these materials, you can create products and structure that are both functional as well as aesthetically pleasing, meeting the needs of various industries.