white epoxy floor cost resin wood price in india zdsticky russia

White Epoxy Floor Cost, Resin Wood Price in India and the Russian ConnectionThe price of resin wood in India, and the Russian connection

In the construction and interior design industries, the costs associated with materials play a crucial role in project planning and budgeting.In the construction industry and interior design, material costs are a major factor in budgeting and project planning. Two such materials that are widely used are white epoxy floors and resin wood.White epoxy floors and resin-wood are two of the most commonly used materials. Understanding their costs, especially in regions like India and their potential connection with the Russian market, can provide valuable insights for businesses and investors.Understanding their costs in India and their possible connection with the Russian markets can provide valuable insight for investors and businesses.

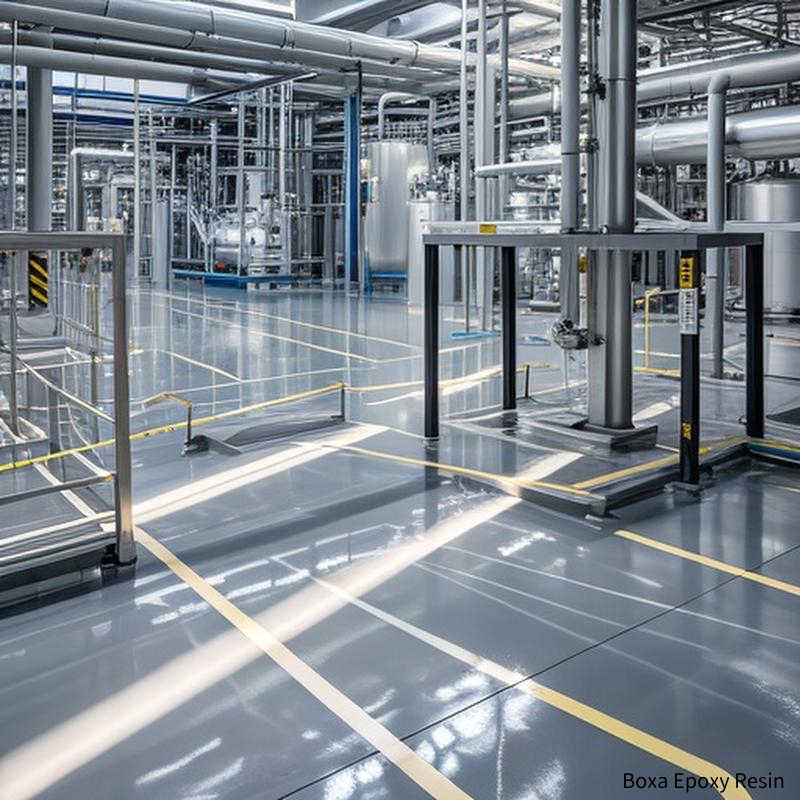

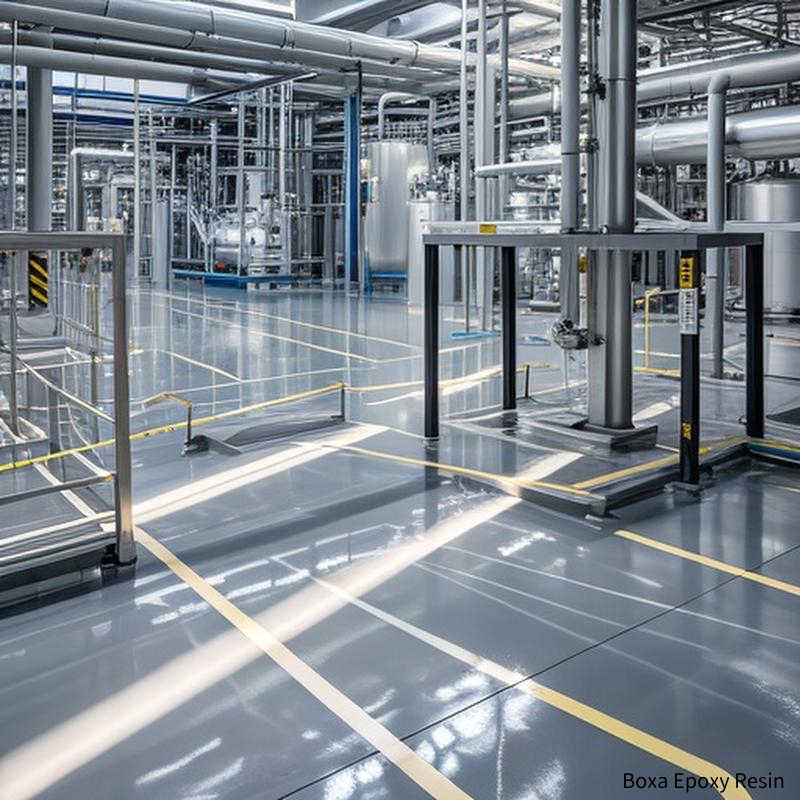

White epoxy floors have gained significant popularity in recent years due to their durability, aesthetic appeal, and easy - to - clean properties.In recent years, white epoxy floors have become increasingly popular due to their durability and aesthetic appeal. They are also easy to clean. In India, the cost of a white epoxy floor can vary based on several factors.The cost of a white floor epoxy in India can vary depending on a number of factors. The quality of the epoxy resin is a primary determinant.The quality of epoxy resin is the primary determinant. High - grade epoxy resins, which offer better chemical resistance, abrasion resistance, and a longer lifespan, will naturally come at a higher cost.The cost of high-grade

epoxy resins will be higher because they offer better chemical resistance, greater abrasion resistance and a longer life span. On average, for a basic commercial - grade white epoxy floor installation, the material cost can range from around 200 to 500 Indian Rupees per square meter.The average cost of a white commercial-grade epoxy floor can range between 200 and 500 Indian Rupees. However, if one opts for a premium - grade epoxy with additional features such as anti - slip properties or enhanced UV resistance, the cost can shoot up to 800 - 1200 Indian Rupees per square meter.If you choose a premium-grade epoxy with added features like anti-slip properties or enhanced UV protection, the cost could be as high as 800 to 1200 Indian rupees per sq. meter.

The installation cost also contributes significantly to the overall expense.Installation costs also contribute significantly to the total cost. Skilled labor is required to ensure a smooth and even application of the epoxy.To ensure an even and smooth application of epoxy, skilled labor is needed. In India, the labor cost for epoxy floor installation can range from 100 to 300 Indian Rupees per square meter, depending on the complexity of the project and the location.The labor cost in India for epoxy floor installation varies from 100 to 300 Indian rupees per square meter depending on the project complexity and location. Urban areas with higher living costs and greater demand for skilled labor may charge towards the higher end of this range.Urban areas with high living costs and a greater demand for skilled workers may charge at the higher end. Additionally, surface preparation is a crucial step.Surface preparation is also a vital step. If the existing floor needs to be levelled, patched, or treated for moisture, these pre - installation steps will add to the overall cost.These pre-installation steps will increase the cost if the existing floor must be levelled, repaired, or treated to remove moisture.

Resin wood, on the other hand, is a composite material that combines the natural look of wood with the enhanced properties of resin.Resin wood is a composite that combines wood's natural look with resin's enhanced properties. In India, the price of resin wood is influenced by factors such as the type of wood used as the base material, the quality of the resin, and the manufacturing process.The price of resin wood in India is affected by factors like the type of wood that was used as a base material, the resin quality, and the manufacturing method. Lower - quality resin woods, which may use cheaper woods and a basic resin formulation, can be found in the market for around 500 to 1000 Indian Rupees per linear foot.Resin woods of lower quality, which use cheaper woods with a basic resin formula, are available in the market at prices between 500 and 1000 Indian Rupees. Higher - end resin woods, often made from premium woods like teak or oak and with advanced resin technologies for better strength and weather resistance, can cost upwards of 2000 Indian Rupees per linear foot.Higher-end resin woods are often made of premium woods such as teak or oak, and have advanced resin technologies to improve strength and weather resistance. They can cost up to 2000 Indian Rupees for a linear foot.

Now, considering the Russian connection.Consider the Russian connection. Russia has a vast and diverse market.Russia is a huge and diverse market. The Russian construction industry has been growing steadily in recent years, especially in infrastructure development, residential construction, and commercial real - estate.In recent years, the Russian construction industry has grown steadily, particularly in infrastructure development, housing construction, and commercial property. There is a potential for Indian manufacturers of white epoxy floors and resin wood to tap into the Russian market.Indian manufacturers of resin wood and white epoxy floors have a lot of potential to tap into the Russian Market. However, there are several aspects to consider.There are several factors to consider.

In terms of white epoxy floors, the Russian climate can be a challenge.The Russian climate can pose a challenge when it comes to white epoxy floors. Epoxy floors need to withstand extreme cold temperatures, which may require specific formulations.Epoxy floors must be able to withstand extreme temperatures, which could require specific formulations. Indian manufacturers would need to invest in research and development to create epoxy products that are suitable for the Russian climate.Indian manufacturers would have to invest in research to develop epoxy products suitable for the Russian climate. This could potentially increase the cost of production.This could increase the cost of production. But if successful, the Russian market offers a large customer base.If the Russian market is successful, it offers a large clientele. The demand for high - quality, durable flooring solutions in Russian commercial and industrial buildings is substantial.The demand for durable, high-quality flooring solutions is significant in Russian industrial and commercial buildings.

Regarding resin wood, Russia has a rich forestry industry.In terms of resin wood, Russia is a country with a thriving forestry industry. This could be both an opportunity and a threat for Indian resin wood manufacturers.This could be a great opportunity for Indian resin wood producers, but it could also be a danger. On one hand, the availability of local wood in Russia may make it more cost - effective for Russian manufacturers to produce resin wood.On the one hand, the availability in Russia of local wood may make it cost-effective for Russian manufacturers to manufacture resin wood. However, Indian manufacturers can differentiate themselves by offering unique designs, better finishing, and advanced resin technologies.Indian manufacturers can differentiate themselves with unique designs, superior finishing and advanced resin technologies. The Russian market also has a growing demand for sustainable and eco - friendly building materials.The Russian market is also growing in demand for eco-friendly and sustainable building materials. If Indian resin wood products can meet these criteria, there is a good chance of success.If Indian resin wood products meet these criteria, they have a good chance to succeed.

In conclusion, understanding the costs of white epoxy floors and resin wood in India is essential for local businesses.Understanding the cost of white epoxy flooring and resin wood in India will be essential for local business. Moreover, exploring the potential connection with the Russian market can open up new avenues for growth.Exploring the potential connection with Russia can also open up new growth opportunities. By addressing the specific requirements of the Russian market, such as climate - suitable products and compliance with local regulations, Indian manufacturers can make inroads and potentially benefit from the expanding construction and interior design sectors in Russia.Indian manufacturers can gain a competitive edge by addressing the requirements of the Russian market. This includes climate-friendly products and compliance with local laws. This cross - border exploration not only has the potential to increase revenues but also to enhance the technological capabilities and market reach of Indian companies in the global building materials industry.This cross-border exploration has the potential not only to increase revenues, but also to improve the technological capabilities and the market reach of Indian building materials companies.